Amid the environmental challenges the country is facing, local bottling firm Pepsi-Cola Products Philippines Inc. (PCPPI) has strengthened its commitment to running a sustainable business through internal solid waste management efforts.

Throughout its 70 years of serving Filipinos world-class refreshments, PCPPI has acknowledged the importance of these measures not just in perpetuating the business but also in ensuring its generational service to the country.

“We strengthened our core commitment to sustainability as we acknowledged that the natural resources we have are limited. Our business and surrounding communities depend on these resources so we resolved to make sure they will continue to be available now and in the future though internal programs we’ve set for ourselves,” said Allan Frias II, PCPPI Senior Vice President for Operations.

One of the measures PCPPI initiated within its business was driving a circular economy—minimizing waste at its source through its internal 5-year Luntiang Yaman program focusing on environmental conservation and development. Under this program they launched a three-pronged approach to solid waste management: Packaging innovations, Recycling, and Partnerships.

Innovative packaging solutions

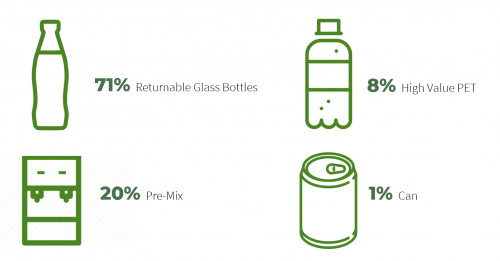

PCPPI has ensured the recyclability of its entire product portfolio—with the bigger share comprised of Returnable Glass Bottles (RGB) at 71%, and the rest comprised of 20% special packaging of pre-mixed beverages for soda fountains, 8% high-value recyclable PET and 1% aluminum can.

“Our product portfolio historically has always been hinged on the returnable glass bottle (RGB) as there continues to be a demand among consumers, and RGBs are a lot sturdier than plastic bottles,” Frias said. “We focus on RGBs because very little needs to be done for their re-use. Our partners return our glass bottles for a fee and all we need to do then is wash and sanitize them.”

Through years of developing RGBs, PCPPI has optimized packaging by reducing the materials in other containers apart from glass bottles by making them lighter, successfully diverting tons of solid waste from landfills. As a result of their packaging innovations since 2014, PCPPI has collectively reduced plastic resin used in its PET containers by 863.4 MT, glass material by 6,467.5 MT, and carton material usage by 921.35 MT.

“Lighter packaging in no way compromises the durability of these containers. The same quality of our products is retained but with added benefit of lessening waste being generated,” Frias explained.

Effective recycling efforts

The Filipino bottling firm also tightened its enforcement of recycling within all of its 13 plants across the Philippines. According to Frias, since the implementation of their Luntiang Yaman program, PCPPI has successfully recycled 81% of in-plant solid waste, putting them right on track to reach their 85% goal by 2020.

“PCPPI embeds recycling even in our community volunteerism projects,” Frias said. “In the past we transformed PET bottles into sustainable sources for light in war-stricken Marawi and recently, in our Brigada Eskwela efforts this year where we turned over a greenhouse made of upcycled PET bottles to one of our beneficiaries.”

Strong Industry partnerships

As sustainability isn’t a competition for PCPPI, the company also leveraged on their industry partnerships to help address solid waste challenges outside their plants.

The company has been a long-time partner of the Philippine Alliance for Recycling and Materials Sustainability (PARMS) alongside other industry movers among Fast-Moving Consumer Group enterprises . “We do not have control over post-consumer wastes, but we try to address this by engaging with our brothers in the industry to help the community have a common recycling facility for all of their wastes,” Frias said. “Here, we segregate our wastes, as well as our partners’ for recycling.”

Further, PCPPI has recently partnered with ABS-CBN Lingkod Kapamilya to donate its used industrial oils, and car in exchange of proceeds that will be remitted to the ABS-CBN Foundation to help fund its projects. The project will not just help divert and properly dispose these harmful leftovers, but aims to help alleviate as well the lives of the beneficiaries.

“When it comes to strengthening business continuity, sustainability must always be a key component. By being more conscious of our responsibility to the environment, we benefit not only our business but the communities that surround and support us well into the years to come,” Frias concluded.